ERP System – Your Assurance of Top Quality with On-Time Delivery

Built Around Precision. Powered by Data.

At Quest Industries, our ERP is central to delivering on our commitment to quality, efficiency, and on-time performance.

“Scheduling and schedule adjustments are critical to maximizing machine utilization and meeting our customer requirements.”

— Dennis Hoover, President

From quoting to final shipment, our goal is simple:

Create the most efficient routing plan and production schedule — delivering the highest quality at the lowest total cost.

Our integrated ERP system ensures your project stays aligned from start to finish.

Integrated ERP Solutions

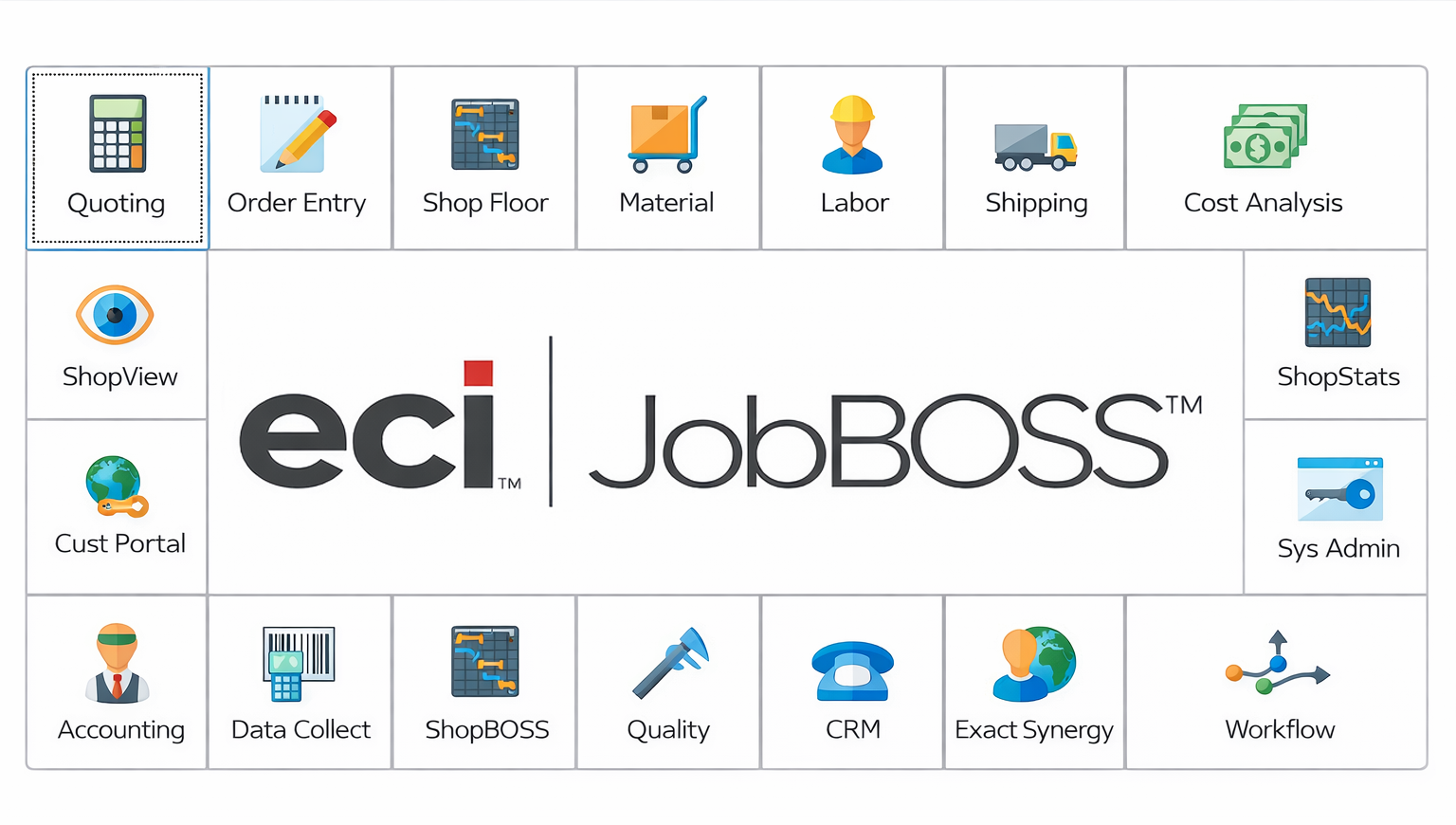

JobBoss – The Operational Backbone

JobBoss serves as our central ERP platform and operational command center.

It manages:

- Quoting and job order processing

- Routing and scheduling

- Purchasing and inventory

- Shipping and receiving

- Capacity planning

Every project detail is housed in one centralized system, creating complete visibility and accountability from kickoff to completion.

UniPoint – Embedded Quality Management

UniPoint is our fully integrated quality management system, directly connected to JobBoss.

It enables:

- Ballooned print tracking

- In-process and final inspections

- Gauge ID tracking

- Equipment calibration records

- Machine maintenance documentation

UniPoint allows us to identify trends, correct inefficiencies, and prevent quality issues before they occur — ensuring consistent, repeatable results.

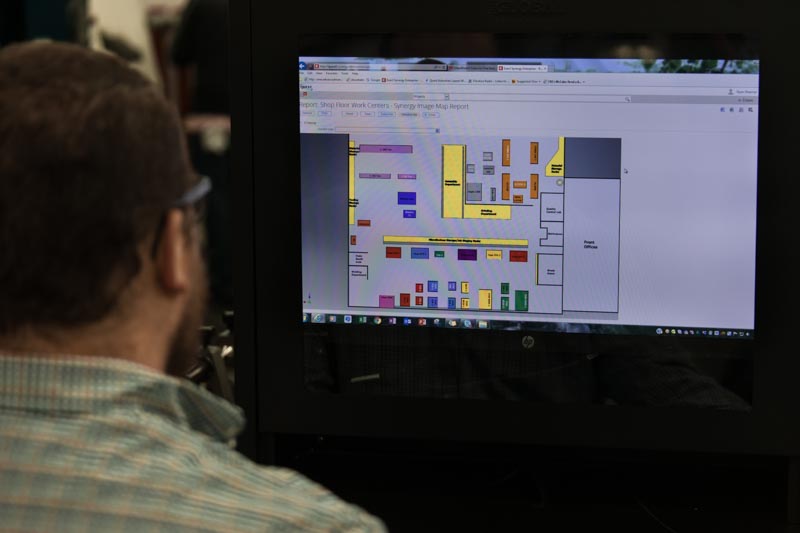

Synergy – Real-Time Operational Intelligence

Synergy is our customized web-based interface that consolidates and enhances data from JobBoss and UniPoint.

Through custom software development, we’ve created a system that delivers:

- Real-time project tracking

- Automated workflow routing

- Sales forecasting insights

- Capacity planning visibility

- Workload estimation

- Fully paperless documentation

Any operational data we generate can be extracted and displayed in a clear, user-friendly format for immediate action.

Continuous Improvement at Quest

“There is always a way to do something better. We have smart people who care and channel their drive for success into our business.”

— Dennis Hoover

Our ERP system is not just software — it’s a continuous improvement tool.

- Every manufacturing cell is equipped with real-time digital displays.

- Schedule adjustments are instantly communicated.

- Completed operations automatically trigger the next workflow step.

- The entire shop floor operates with full visibility.

The result is a streamlined, responsive manufacturing environment that adapts instantly to change.