Plastic Injection Molding Services

Print-to-Production Injection Molding Under One Roof

If you’re searching for a single partner to take your plastic part from design and tooling through full production molding, Quest Industries provides complete, in-house plastic injection molding services.

We design, manufacture, and validate injection mold tooling, then run low-volume, high-volume, and long-term production molding programs — all within one integrated operation. Customers choose Quest for the simplicity, accountability, and confidence that comes from working with one company that can do it all.

Full-Service Injection Molding Capabilities

Quest Industries supports the complete lifecycle of plastic part manufacturing, including:

- Injection mold design and build

- In-house mold tryouts and sampling

- Prototype injection molding

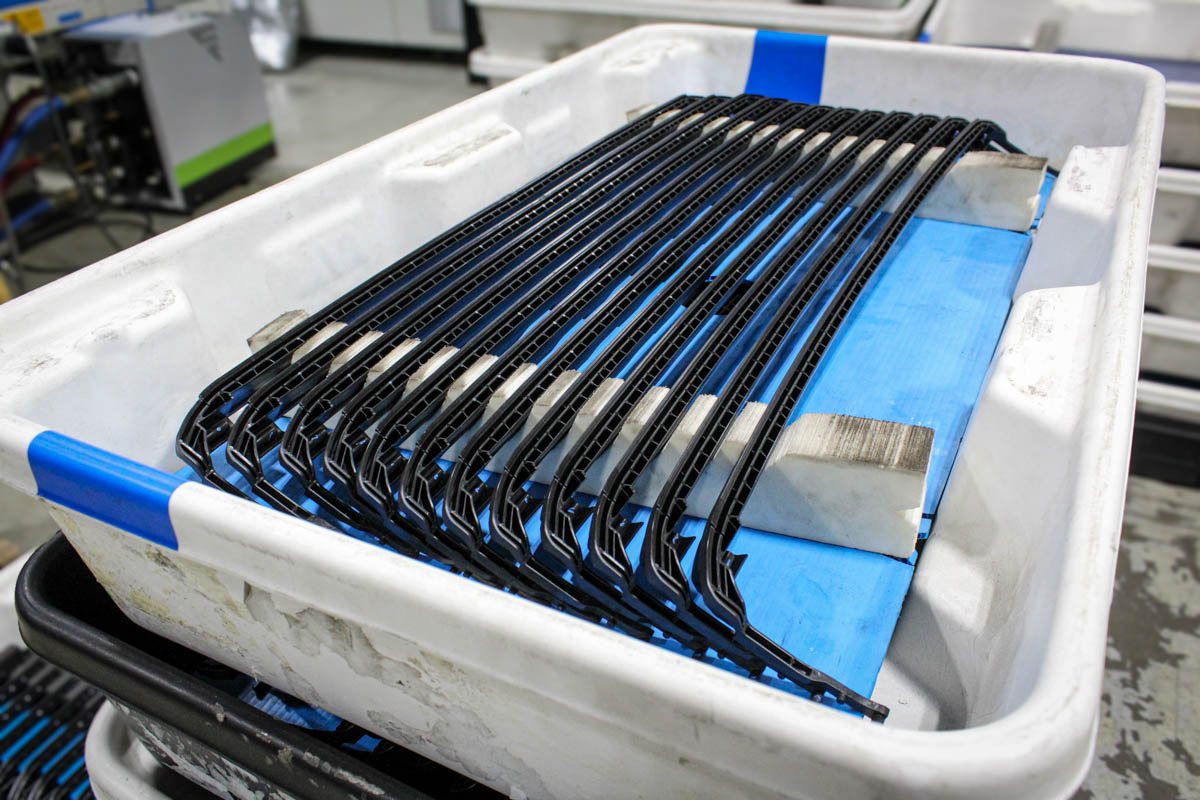

- Low-volume production molding

- High-volume, contract production molding

What began as internal mold sampling and short-run molding has grown into long-term, repeatable production programs across automotive, medical, industrial, and consumer markets.

Production Injection Molding — Built to Scale

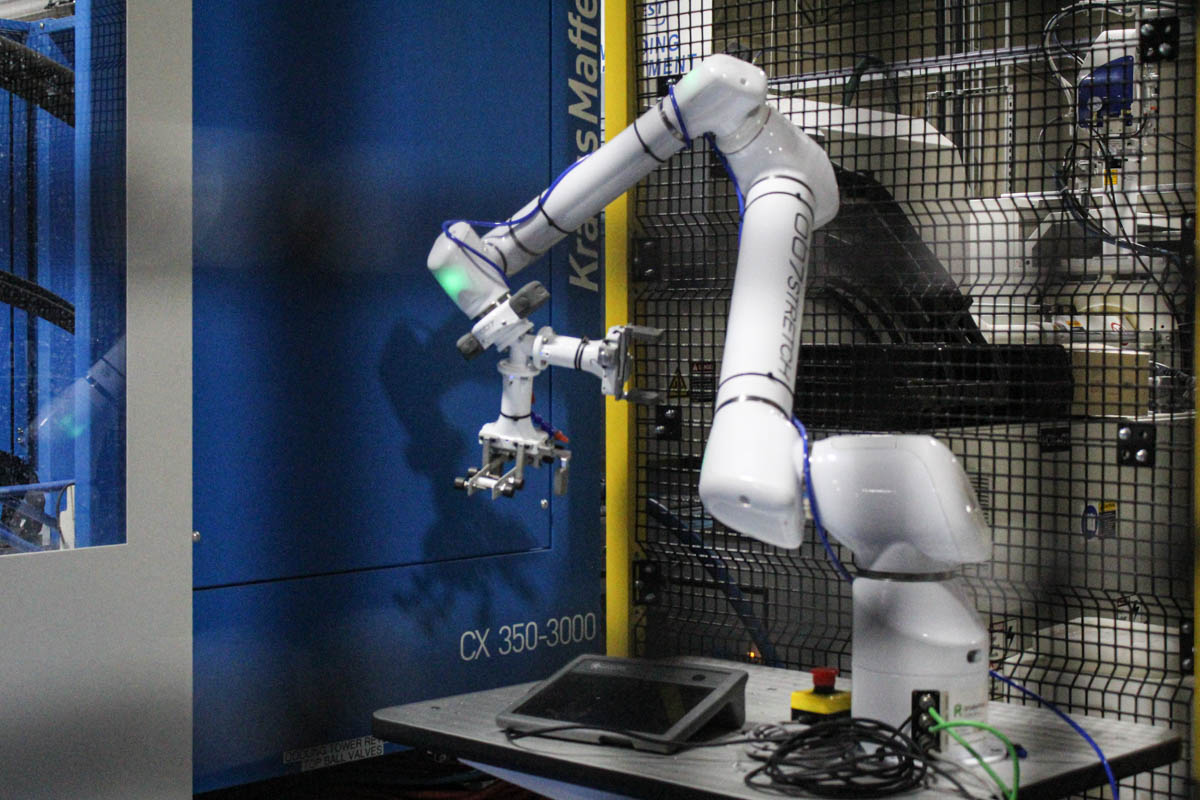

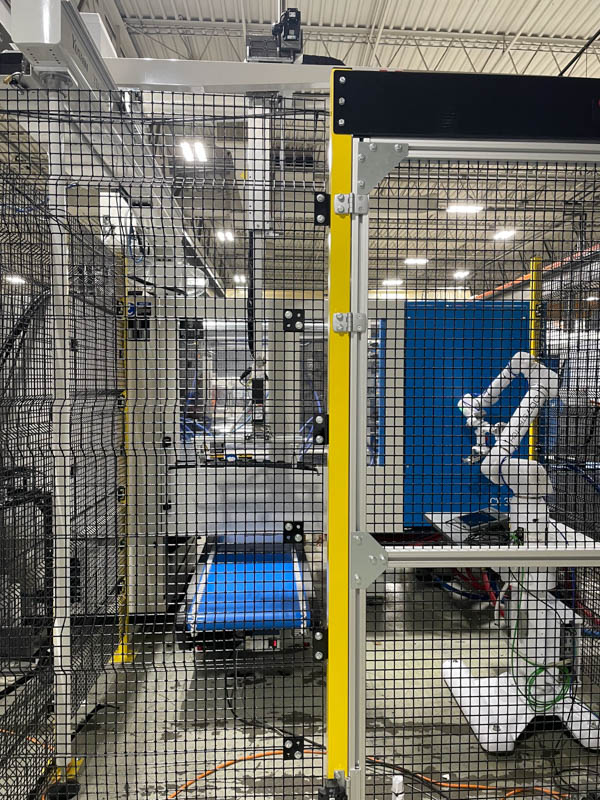

Production molding is optimized by integrating cells with automation features like sprue pickers, robots and cobots, and conveyors.

Production molding is optimized by integrating cells with automation features like sprue pickers, robots and cobots, and conveyors.As demand for production molding increased, Quest made targeted investments to support automation, repeatability, and capacity growth.

Since 2024, we have added four new injection molding machines, three of which are all-electric, and integrated them with advanced automation systems including:

- Overhead take-out robots

- Sprue pickers

- Multi-axis collaborative robots (cobots)

- Conveyors and material handling systems

- Dryers and auxiliary equipment

This state-of-the-art molding cell layout allows Quest to support consistent cycle times, reduced variation, and scalable production volumes.

Industries Served

Quest Industries is IATF 16949 certified and produces plastic injection molded components for major OEMs and Tier suppliers, including programs supporting Tesla, Volvo, Ford, GM, Lucid, and others.

Our injection molding experience spans multiple industries, including:

- Automotive

- Medical devices

- Industrial products

- Consumer products

- Custom engineered plastic components

Quality Systems & Process Control

Quality is embedded into every stage of our injection molding process.

- Electronic scheduling and routing ensure accuracy and traceability

- A dedicated Plastics Quality team oversees validation and inspection

- Quality tools and systems include:

- CMM inspection

- Laser scanning

- Checking fixtures

Our process technicians are trained in scientific molding principles and certified as RJG Master Molders. Dedicated Plastics Engineers from Ferris State University oversee program management, tooling validation, and production execution.

This disciplined approach ensures repeatable quality, predictable launches, and on-time delivery.

Secondary & Post-Molding Operations

Many Quest injection molding programs require additional processing beyond molding. We work closely with qualified suppliers to deliver fully finished plastic parts, including:

- Painting

- Pad printing

- Laser engraving

- Additional secondary or finishing operations

Our goal is to deliver complete, production-ready components, not just molded parts.

Injection Molding Services

- High-volume production injection molding

- Low-volume production injection molding

- Prototype injection molding

- Mold tryouts and validation

Injection Molding Equipment

Krauss Maffei PX 250-1000 Plastic Injection Molding Press with parts conveyor system

Krauss Maffei PX 250-1000 Plastic Injection Molding Press with parts conveyor systemElectric & Hydraulic Injection Molding Machines

- 81PX Electric Krauss Maffei

- 7.25 oz shot

- Yushin overhead sprue picker

- 161PX Electric Krauss Maffei

- 9.28 oz shot

- Overhead robot (coming soon)

- 250PX Electric Krauss Maffei

- 16.79 oz shot

- 350CX Krauss Maffei

- 51.62 oz shot

- Yushin YD2 overhead take-out robot with servo wrist

- OB7 7-axis collaborative robot

- 85-Ton Milacron

- 4.4 oz shot

- 165-Ton Milacron

- 11 oz shot

Partner With Quest Industries for Injection Molding

Whether you need prototype molding, production injection molding, or a full print-to-production plastic manufacturing partner, Quest Industries has the equipment, expertise, and systems to deliver.

Contact Quest Industries today to discuss your injection molding project.